Our Innovative Solutions

Compliance to strict emission limits, such as Euro 6, is a challenge for the emission system. The pollutants carbon monoxide (CO), hydrocarbons (HC) and nitrogen oxides (NOx) need to be reduced as well as soot (PM). Our mission is to deliver cost-effective solutions for these increasingly stringent emissions control regulations.

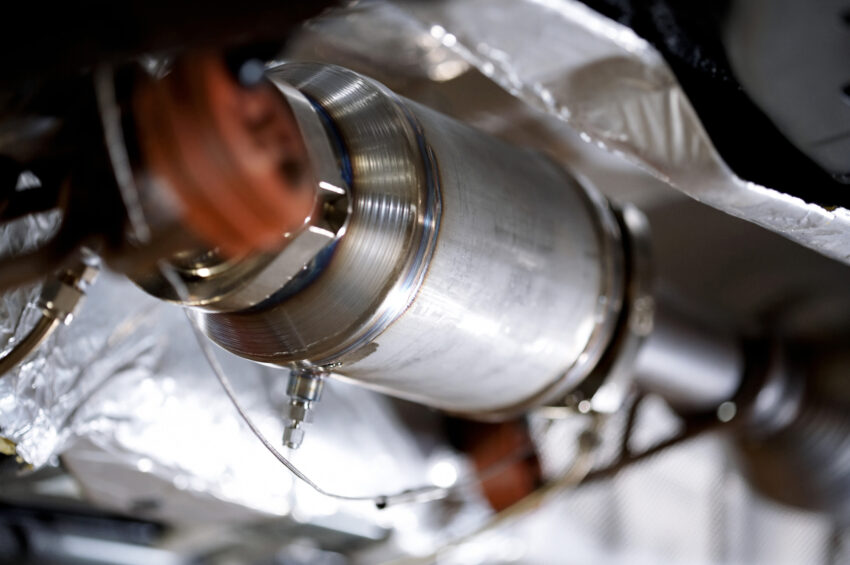

Diesel Oxidation Catalysts (DOC)

BASF's Diesel Oxidation Catalyst (DOC) technology controls emissions of hydrocarbons (HC), carbon monoxide (CO) and particulate matter (PM) from diesel vehicles.

It was the first catalytic emissions control system to meet U.S. Environmental Protection Agency (EPA) certification requirements for the U.S. Urban Bus Retrofit Program, and offers many benefits:

Can reduce HC and CO emissions by 50% or more

Integrated, easy-to-install bolt-on technology

Fuel sulfur tolerance

Easy maintenance; needs no additional parts or sensors

U.S. EPA approved for two- and four-stroke diesel engines

BASF DOCs have millions of miles of proven performance in light duty passenger car, urban bus, medium duty truck and heavy duty truck applications. BASF DOC technology platforms and precise patented manufacturing process enable BASF to provide DOC technologies that light off at very low temperatures using a minimum amount of precious metal. The catalysts are also currently in use on tens of thousands of retrofitted vehicles around the world.