Durasorb® RSH

Specialty Aluminosilicate Gel adsorbent for the removal of mercaptans in Durasorb® LNG MAX technology to reach cryogenic specifications.

Technology

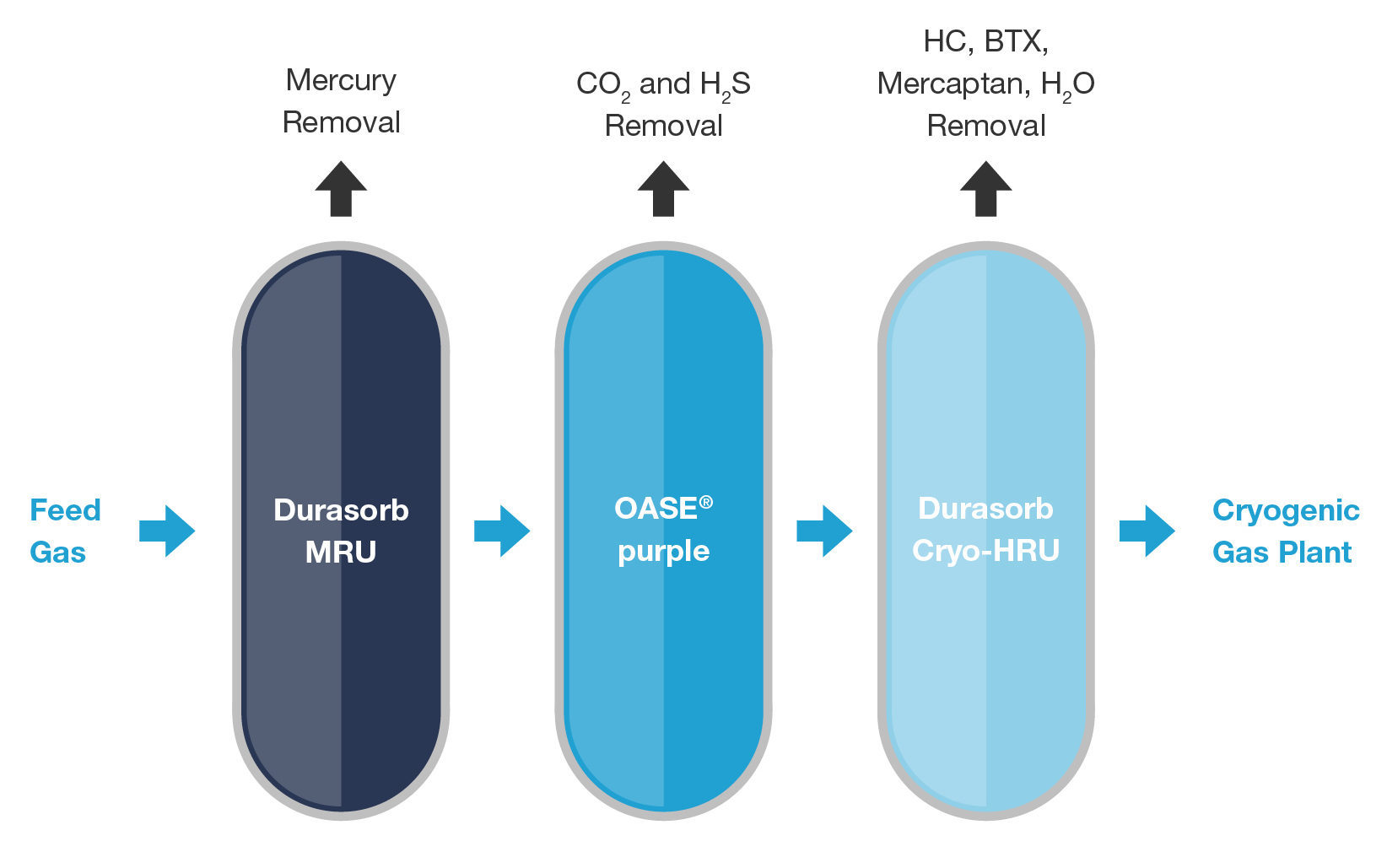

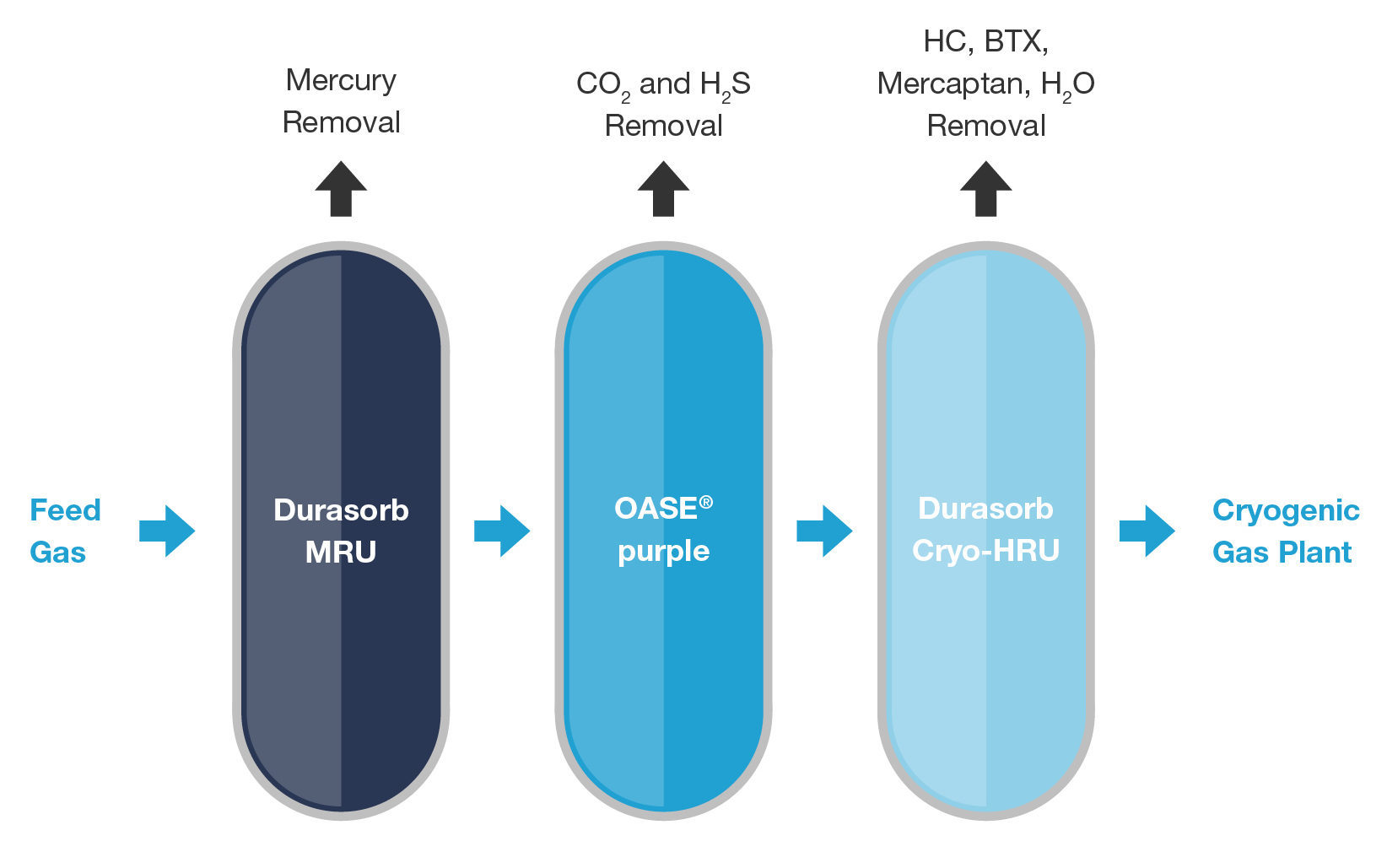

Durasorb® LNG MAX technology combined with a standard AGRU process offers a proven alternative to the conventional technologies. The process line-up is simpler, requiring less equipment and a smaller footprint, allowing projects to achieve up to 30% lower CapEx. BASF Adsorbent experts design the unique layer bed to remove mercaptans, heavy hydrocarbons, and water.

Durasorb® Cyro-HRU with Durasorb RSH adsorbent is a unique solution with significant CAPEX savings

Durasorb® HD is a water stable adsorbent that protects the bed from liquid hydrocarbon and water carry-over

Durasorb® RSH is capable of adsorbing and desorbing hydrocarbons and mercaptans:

Adsorption of mercaptan components

Co-adsorption with heavy HCs facilitates regeneration gas scrubbing, leaving less RSH in gas phase

Has a lower heat of adsorption compared to molecular sieves, so RSH and HC compounds are easily driven off during regeneration

Adsorbent is resistant to typical acidic components

Durasorb® HR is a reflux resistant molecular sieve that removes water to cryogenic specifications

Durasorb® LNG MAX with Durasorb RSH

Simplified line-up for treating natural gas containing mercaptans: Standard Amine followed by Durasorb® LNG MAX

BASF Durasorb® LNG MAX technology can remove mercaptans from natural gas and provides an improved alternative to the conventional molecular sieve option. Durasorb® LNG MAX technology is installed downstream a standard acid gas removal unit (AGRU) and removes mercaptans, heavy hydrocarbons (C6+), and moisture to cryogenic specifications. BASF natural gas experts have a broad portfolio of specialized products and proprietary simulation software to design a layered bed configuration to meet the specific needs of the project. For projects with mercaptan concentrations ranging from 100-700 ppm, Durasorb RSH, a specialty aluminosilicate gel material, is chosen for its high capacity and acid resistance. Durasorb RSH can remove mercaptans to below 1 ppmv and can withstand over 10,000 regeneration cycles over a lifetime.

Compare to conventional technologies:

Hybrid AGRU followed by standard Molecular Sieve

Hybrid amines co-adsorb hydrocarbons, which are lost to the Sulfur Recovery Unit (SRU), resulting in a loss of revenue stream for the operator. The Durasorb LNG MAX solution eliminates the need for a hybrid solvent in the AGR process because it does the work of removing hydrocarbons and mercaptans.

Standard AGRU followed by Molecular Sieve with physical solvent wash

This approach requires an additional physical solvent process for removal of mercaptans from the spent regeneration gas. Such a solvent process will result in high CapEx and OpEx for the plant. In the Durasorb® LNG MAX process, mercaptans are recovered as condensate along with heavy hydrocarbons, so additional equipment to treat the regeneration gas is not required.

Publications

Struggling to remove mercaptans and keep project costs in line? Time to consider Durasorb® LNG MAX!

BASF References:

- Kazakhstan gas processing plant: RSH removal along with HC dew point control

- Bangladesh gas processing plant: RSH removal along with HC dew point control

- Malaysia gas processing plant: RSH removal upstream membrane unit

- Germany Under Ground Storage unit