With our strategy to maintain a leading cathode active material (CAM) producer for electrified vehicles around the world, we are executing on a couple of important strategic projects. Research and development activities combined with acquisitions have delivered a unique technology portfolio for lithium-ion batteries. We are working with customers, partners to jointly develop innovative battery materials, processes and technologies for current and next-generation lithium-ion batteries and future battery systems.

The “big bang” happened in 2012, when our battery materials business within BASF was established. Since then, we have strived to build a global footprint for production and research and development to serve our customers. We believe that being close to our customers is key to having a successful partnership in driving electromobility forward.

Let's do a time travel journey to some of our key developments.

In 2015, we partnered with Toda Kogyo and established a joint venture known today as BASF Toda Battery Materials (BTBM). Fast forward two years, and in 2017, we announced that the capacity at BTBM has nearly tripled at its Sanyo-Onoda site in Japan. This accomplishment made us a leading supplier of high-energy density cathode active materials (CAM) for the automotive industry, serving the leading electric vehicles OEM among others.

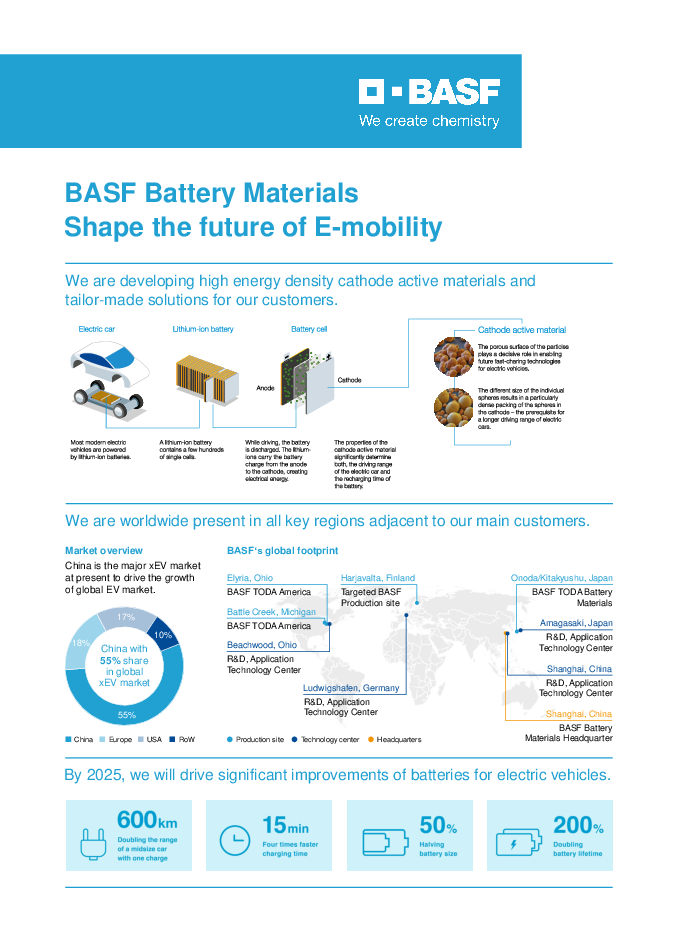

With ambitions to be one of the leading supplier of battery materials worldwide, we had signed an agreement with TODA to form a second, BASF majority-owned company, known as BASF TODA America (BTA) to serve global and local customers in North America in the end of 2017. Our BTA joint venture allowed us to consolidate production assets between plants in Elyria, Ohio and Battle Creek, Michigan for cathode active materials. We are also having a highly-experienced researcher and scientist team in Beachwood, Ohio for broad R&D activities. Our business operations in North America reinforce the emphasis BASF places on the battery materials market.

Another step into 2018, BASF revealed the European Battery Material Investment (EBMI) to enter the second largest market globally with the highest growth and the prospect of investments of major global cell manufacturer. This investment highlights two large initiatives for us: A plant focused on producing precursor of cathode active materials (pCAM) in Harjvalta, Finland, and in 2020, we announced our second part of the investment - a plant in Schwarzheide, Germany, for production of CAM. This setup combined with the strategic partnership on proximate metal supply in Finland brings us into a unique position in Europe to offer a secure and reliable value chain to our customers from 2022 onwards.

Both European sites are constructed to rapidly scale up to meet the industry’s demand and related challenges ahead.

With these investments in Finland and Germany, BASF will be the first CAM supplier with local production capacities in today’s three major markets – Asia, the U.S. and Europe.

And we're not stopping there.

By further strengthening our market position through strategic partnerships along the value chain, we like to secure sustainable raw materials supply and serve our customers with highest standard on product quality and performance, as well as sustainability.