Making BASF the partner of choice for customers: Building a sustainable battery value chain for electromobility

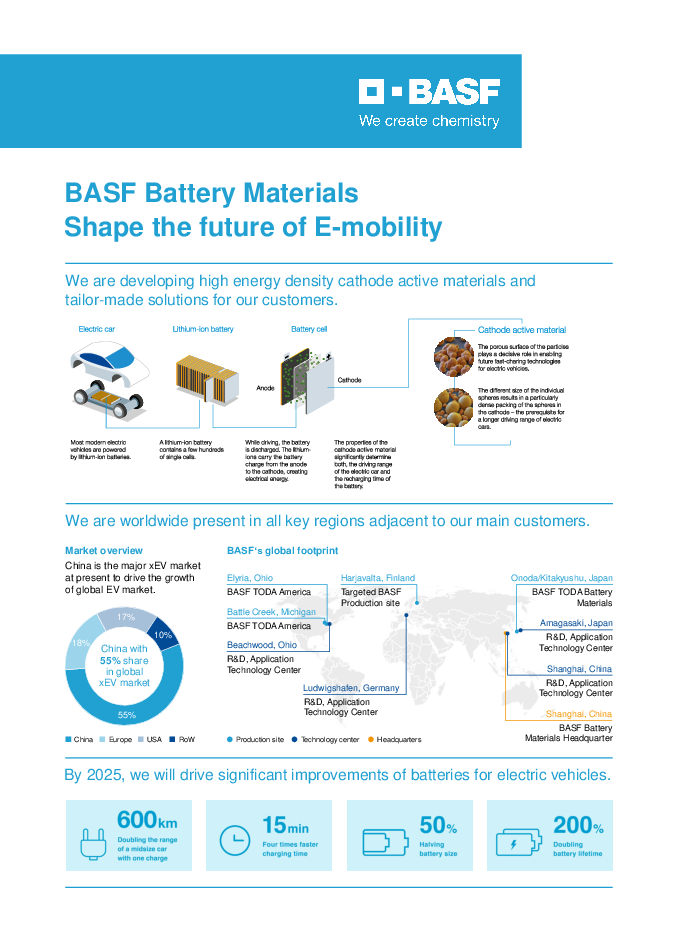

Let's be honest. By now, you have read the news and you have seen the OEM's slowly shift focus to highlight e-mobility efforts within their line of automobiles. The expectation of producing 145 million electric vehicles, including hybrids, by the end of 2030* isn't far off from reality. Battery cell manufacturers are investing and building production factories similar to a Gigafactory in size, with an increased focus around Europe. Though we have recently made significant investments in Europe with our two new production sites in Harjavalta, Finland, and Schwarzheide, Germany, we are also aiming to establish a global footprint in the Asia and North America markets through various partnerships and joint ventures.

One of the most critical pieces of technology that powers an electric vehicle is known as the lithium-ion battery. Within the lithium-ion battery is a component known as cathode active materials (CAM). CAM is crucial in the overall performance of electric vehicles.

With demand increasing for electromobility worldwide, the market for CAM will be monumental. Market demands are projected to be worth billions globally, with a steady growth rate on a continued basis year-after-year. Though the Asia market has had the highest growth historically, electric sales in Europe had actually surpassed Asia for the first time in the first half of 2020.

Inside the chassis of the electric car

It is also important to highlight the efforts being made globally around what to do when an electric vehicle reaches its end-of-life. We simply cannot just toss the vehicle to the junkyard, but instead have found innovative solutions through partnerships and collaborations to find ways to recycle the materials from lithium-ion batteries. At BASF, we are working on developing "close-the-loop" solutions to save the critical metals from these end-of-life batteries and recycle them into building new batteries to enable a circular economy.

Learn more about our battery materials business or our battery recycling initiatives here.

Our commitment to contribute to a sustainable battery value chain and our customers’ success

We are partnering with companies around the globe to secure regional, sustainable metal materials supply to make sure that our battery value chain is maintainable. Our commitment to sourcing raw materials in a responsible and sustainable manner is key to our success in creating this sustainable value battery chain. As a global automotive supplier with sufficient resources to support growth and the solid experience to successfully execute investment projects in all regions, BASF is building upon a solid and proven foundation to achieve the success of our battery materials business: a strong team, leading technology capabilities in CAM, global manufacturing setup and expertise, metal management capabilities and strong partnerships. You can learn about our battery materials history here.