Presenting BASF’s path forward around cathode active materials

BASF – We create chemistry for a sustainable future

At BASF, we create chemistry for a sustainable future. Sustainability is in our DNA.

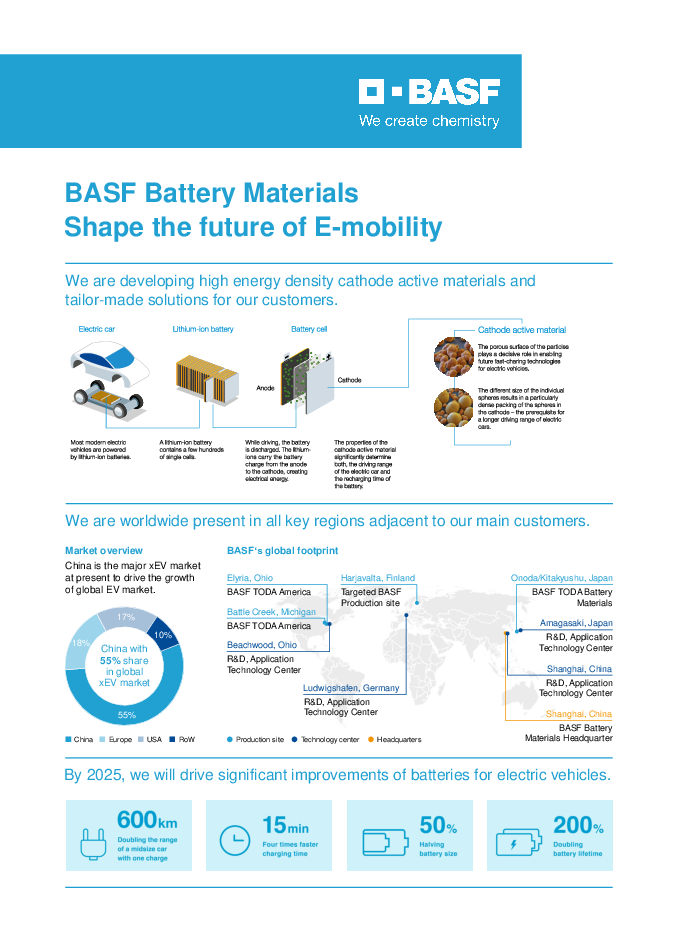

This year, we announced our intention to reduce our absolute CO2 emissions by 25 percent by 2030, compared with 2018 and aim to achieve net zero emissions by 2050. Battery Materials and in our case cathode materials are one of the biggest growth areas of the chemical market. Between 2020 and 2025, BASF will invest significant amount of money in our battery material business. Our goal is to become a market-leading CAM supplier with the best-in-class sustainability and CO2 footprint globally.

BASF aims to become the most sustainable CAM producer globally by taking responsibility throughout the battery value chain

Cathode materials are a wonderful example for the importance of sustainable chemistry in many value chains for downstream industries – in this case for the automotive industry. A lot of the sustainability challenges also beyond just the CO2 footprint are hidden with the raw materials and as the leading chemical company we also want to be a leader in changing this. It is worth to take a deeper look at the various processing steps and their sustainability challenges and how we at BASF try to tackle this:

① We must begin at the mines and metal refineries. This is one of the key contributors of the CO2

footprint of the battery as minerals or metals like Nickel, Cobalt or Lithium are many times only available in very low concentration in the respective ore bodies. Isolating and refining metals requires a lot of energy. Also, some of these metals will become very scarce given the growth expectations which seem to accelerate given the many recent announcements. We will partner up globally to ensure a resilient, sustainable and robust metal supply chain.

② Metals need to be converted into an electrochemically active material. The cathode material is the key raw material that drives performance and a lot of the cost of a battery. In fact, this requires two steps: A precursor production – abbreviated with PCAM and a cathode active materials production named CAM. Also, in this case production is very energy intensive at temperatures above 600 °C and energy efficient production is key to reduce the CO2 burden further.

③ So far, the supply for cell manufacturers in Europe and in North America almost exclusively relies on deliveries from Asia. We believe that this is not sustainable and the risk of significant supply disruptions would not come as a surprise. Our global production footprint ensures customer proximity and our modular expansion concept allows us to be a reliable growth partner for our customers to support the massive transformation ahead of us.

④ We invest in recycling! Recycling for battery materials requires again smart chemistry to achieve highest metals recovery returns with lowest energy input. By offering the best-in-class CO2 footprint, BASF can help further reduce the CO2 burden of EVs – over time we would like to close the loop to avoid further resource and CO2 intensive mining and refining. Let’s take a look at how we want to tackle these topics.

Sustainable metals and customer proximity

One of the major challenges facing the battery value chain is the supply of metals and offering our services closest to our customers. For electromobility and batteries we need more chemistry and materials than for a combustion engine and the exhaust system. While for our automotive catalysts a few grams of precious metals are enough, electrical vehicles will need easily more than 50 kg up to 70kg of metals. The relevant natural resources are limited to only a few geographical locations. The metals also are a major cost driver of battery materials and consequently the battery cells. We are responsibly sourcing metals needed for cathode active materials globally to ensure a resilient and sustainable metal supply chain for our customers. With mining partners we will ensure a regional, resilient and sustainable supply chain for Nickel and Cobalt in Europe. In Asia, we assess with a partner the development of a joint Nickel and Cobalt refining complex in Indonesia. There is potential to secure sufficient Nickel and Cobalt, enough for more than 80 kt of high Nickel containing cathode materials. We are a founding member of the GBA – the global battery alliance.

The GBA currently develops an intelligent tool:

The battery passport which will become a digital twin of each battery.

It should become a kind of quality seal as it provided relevant sustainability data starting with GHG emissions and social compliance.

Europe accelerates

We have seen in 2020 how crucial securing local supply is for the industry and the global economy. Various supply chains also in the automotive industry lead to costly supply interruptions. Currently North American and European supply chains rely almost exclusively on battery raw materials being shipped from Asia. Whilst we see a mushrooming of European cell production capacity, their demand is initially only covered by 1/3 by European CAM production. In case of acceleration of the market development this gap will even widen.

In BASF we always believed in having the supply of key raw materials in close customer proximity. We believe that a local production and local content for battery materials are key to ensure a resilient and sustainable supply chain. That’s why we decided to invest into two new production sites in Europe. Our new plants for precursor materials in Harjavalta, Finland and cathode active materials in Schwarzheide, Germany will come on stream next year. This will not only shorten logistical routes; we will also reduce our dependence on imports from remote areas. Together with our established production plants in Asia and the US, BASF will be the first truly global cathode active material producer in the world to support the rising demands of our customers in all regions locally. And our new modular plant concept can easily be scaled up to flexibly accommodate our customers’ demands and to close the gap for local content based on very energy efficient production combined with a high share of renewable energy.

Customized Solutions

BASF is at the forefront of pushing cathode active materials (CAM) innovation to meet our customers’ needs:

- We have the technological flexibility to support our customers by tailoring our products to their exact needs: For example, higher driving range or faster charging times.

- We currently offer a broad CAM portfolio in the industry with a focus on Ni-rich NCM products and low or even no Cobalt for high energy density

The current trend is towards materials with more than 80, even more than 90% Nickel. This is not easy. Morphology, chemical composition and powder processing are key levers to achieve optimal performance. By using special coatings and dopants, we finetune the chemistry of our products. Despite the trend to reduce cost and a drive for standardization the market for CAM materials will become more differentiated over time and a strong technology toolbox is essential to be in a leading position of this developments. One example will be Mn-rich products for which we have a very strong IP position. This new product family that will play a crucial role in future for the low cost segment Manganese is abundantly available at much lower cost than Nickel or Cobalt. Supply seems to be not constraint which is de-risking the challenge of surging metal price that the industry is experiencing in this moment for automotive catalysts in this case in particular for Rhodium but also palladium. In short: We customize materials to optimize the balance of energy density, fast-charge capability, cost and stability according to the requirements of our customers.

Responsibility throughout the lifecycle

The overarching goal of a sustainable battery value chain is to “close the loop” and create circularity. By 2030, we will see around 1.5 million metric tons of end-of-life batteries. Considering the growing demand of critical metals, the availability and CO2 impact of mining and refining, recycling is the inevitable way to go. The metal content of spent batteries will be higher than what we can find in natural ores.

BASF has extensive history in the recycling industry and is a market leader for precious metal recycling of automotive catalysts. Like for precious metals eventually we want to run large scale urban mines which long-term will become the most sustainable metals source for the battery materials industry. We form strategic partnerships to bundle resources and are looking into different opportunities of this important puzzle of the battery value chain.

We are currently preparing to build a recycling prototype plant in Schwarzheide next to our new CAM plant covering all steps of the recycling value chain, which will be in operation in early 2023. We will be able to chemically extract battery grade Lithium which is one of the key value drivers in battery recycling next to the capability to achieve highest recovery returns on the metals. Recycled metals in future battery cells will reduce their CO2 burden by minimum 25% helping our customers meet their sustainability goals.

As a result of our holistic approach, we can offer CAM products with best-in-class CO2 footprint and have concrete plans to do even more!

Let’s look even more thoroughly into the CO2

footprint for batteries. Battery production produces more than 40% of the total carbon dioxide in the manufacturing process of modern e-vehicles. Half of this comes from the production of the cathode material. We should be aware that subject to the origin of the battery material around 13g CO2 per kilometer driving range could result from the CAM material alone. This could be even worse in case of energy intense processes are used along the value chain which is currently a reality in some of the existing supply chains. With our holistic approach, we can offer CAM products with best-in-class CO2 footprint.

There are 4 key measures behind this:

① BASF's production processes are so intelligently developed that they require significantly less energy than those of other players, which today are mainly located in Asia. We are talking about a reduction in electricity consumption of more than 45%!

② Our plants are powered by electricity that has a low carbon footprint or is generated from renewable energy sources.

③ Our raw material partner uses a very abundant nickel ore and has one of the lowest CO2 emissions in the nickel industry when producing the metal.

④ And last but not least, fourth: The significantly shortened supply chains contribute their share to this favorable overall CO2

footprint.

This means that our cradle-to-grave emissions will be less than 10 g CO2 per km driving range. Our cathode active materials thus have a CO2 impact that is at least 30% lower than what we see today in e-vehicles on European roads. In the future, we can do even better with our innovative process for recycling battery raw materials. This will enable us to close the loop and reduce CO2 emissions by up to 60%.

Future perspectives

To wrap it up: the mobility transformation is happening now! Society and the political environment are changing, and so is the industry. And considering climate change accelerating, the industrial transformation is needed at a very challenging pace. We, the chemical and automotive industry, are charged with establishing a sustainable value chain and taking responsibility for it. We should do it right from the very beginning and need to understand that the problem is not solved by a hardly any CO2 emission for an electric car in the future.

Only a sustainable battery value chain will meet global society’s needs and create a true sustainable future. We will not stop there, but also work on disruptive innovations of the future. We partner and research on next generation systems although the chemistry for solid state batteries has its known challenges and it will take a while. However, lithium-metal based anodes which will allow for a step change in energy density could become viable together with our partner Sion Power and their Licerion™ technology. We are all part of this one planet. And we as BASF, are committed to take this challenge, grow sustainably, and create an impact.